|

| December 08, 2020 | Volume 16 Issue 47 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Army gets closer to self-adjusting turbine engines

A new design could enable automatically adjusting aircraft rotor blade positions mid-flight. [Credit: U.S. Army]

A team of U.S. Army and academic researchers at Aberdeen Proving Ground in Maryland has developed a novel design to automatically adjust aircraft engine rotor blade positions while already in flight, a tactic that could improve turbine engine performance.

Researchers from the U.S. Army Combat Capabilities Development Command (now known as DEVCOM), the Army Research Laboratory (ARL), Iowa State University, and Brown University used Army supercomputers to conduct coupled computational fluid dynamics and surrogate model analysis to develop new variable-speed concepts, particularly during dynamic movements. This discovery could improve performance of Army helicopters and other machinery using turbine engines such as turboshaft, turbofan, or turbojet powered aviation vehicles across the DOD and the civilian sectors, as well as power plant designs.

"Today's gas turbine engines are optimized to produce peak performance at a single design speed with fixed blade geometries for a specific operating condition," said Army aerospace engineering researcher Dr. Luis Bravo. "This limitation creates drastic performance losses when operating away from the optimal design point, such as during takeoff or landing, or when conducting sudden maneuvering. The variable-speed concept improves performance by maintaining blade aerodynamic efficiency within the optimum range at all operating conditions."

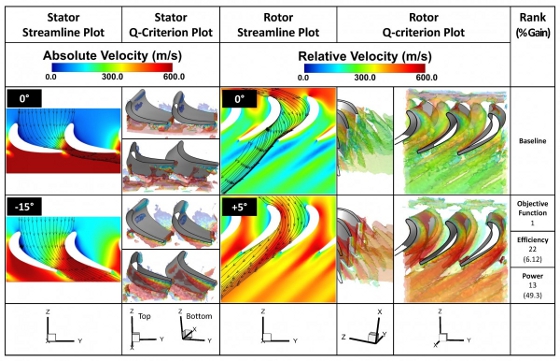

Researchers view flow field comparison using streamline and Q-criterion plots between the optimal and baseline cases. The stator plots use absolute velocity, while the rotor plots use relative velocity. [Credit: U.S. Army]

A patent application on the Army's concept of self-adjusting flow incidence-tolerant blade design is with the U.S. patent office, said Army aerospace researcher Dr. Muthuvel Murugan, who works with this research team.

The research team demonstrated their simulation framework through the modeling, analysis, and optimization of an Army rotorcraft gas-turbine engine, such as the T-700 engine powering Apache and Black Hawk rotorcraft.

"High-fidelity modeling provides superior accuracy in turbine engine design," Bravo said. "However, this level of precise modeling comes with relatively high computational cost in order to achieve optimal design. To reduce the amount of design iterations needed for this high degree of accuracy, we used a surrogate framework, based on a statistical sampling method and a precise optimizer to select the best performance. This achieved optimal design of the gas turbine at a much lower cost."

Cutaway of typical rotorcraft engine turbomachinery powering the Army's Black Hawk and Apache fleet. [Credit: U.S. Army]

The team studied the aerodynamics in an annular high-pressure turbine rig using active flow control methods on the rotor blades that allowed precise adjustments of the throat area. The team also examined typical rotorcraft cruising conditions, specifically by determining the stator- and rotor-blade optimal positions during design and off-design engine operations, at 50%, 75%, and 100% of the rotor speed. Using the proposed framework, the researchers gained significant improvements of 6.1% for the turbine efficiency and up to 49% for the shaft output power. These results are critical to extending variable-speed engine concepts that provide more power while reducing operating costs for turbine-powered vertical lift vehicles.

"Efficient variable speed engine technology can enable advanced rotorcraft using slowed or optimized rotor configurations to achieve increased speed or range capability," said Kevin Kerner of the DEVCOM Aviation and Missile Center.

The team published its research, "Optimizing gas turbine performance using the surrogate management framework and high-fidelity flow modeling," in an Army-led special issue of the peer-reviewed journal Energies, Advancements in Multiphase Fluid Dynamics in Energy & Propulsion Systems.

"The idea of a self-adjusting engine came from morphing systems," said Dr. Anindya Ghoshal of the Army Research Lab. "ARL is taking these self-adjusting engine concepts to develop a futuristic convertible engine concept that will enable future Army aviation systems to go supersonic or transonic at cruise, while enabling highly efficient hover."

The research team plans to continue this work by developing an experimental prototype and extending this methodology to multi-stage engines, and investigating the benefits of active flow control in coupled pulsed combustor designs. The research team will continue to disseminate their results to Army aviation communities to inform current platforms and future development and modernization efforts.

Source: U.S. Army DEVCOM Army Research Laboratory

Published December 2020

Rate this article

View our terms of use and privacy policy